Create More With BobCAD-CAM V36

Reduce Costs | Finish Faster

BobCAD-CAM V36 adds more features and enhances existing modules.

2-5 Multi Axis Milling, Lathe / Mill Turn, Wire EDM, BobART

Discover the exciting enhancements in BobCAD CAM V36, designed to simplify your experience, whether you’re a beginner or a seasoned pro.

This version optimizes tasks like version migration and entity selection, while also providing you with advanced features like customized tool creation for roughing operations and an enriched new interface option in the CAM Tree loaded with fresh capabilities. Don’t miss out on the chance to explore the latest and most valuable additions to BobCAD CAM V36.

Whether you’re a new user, or already part of the family, this version is going to improve your work flow!

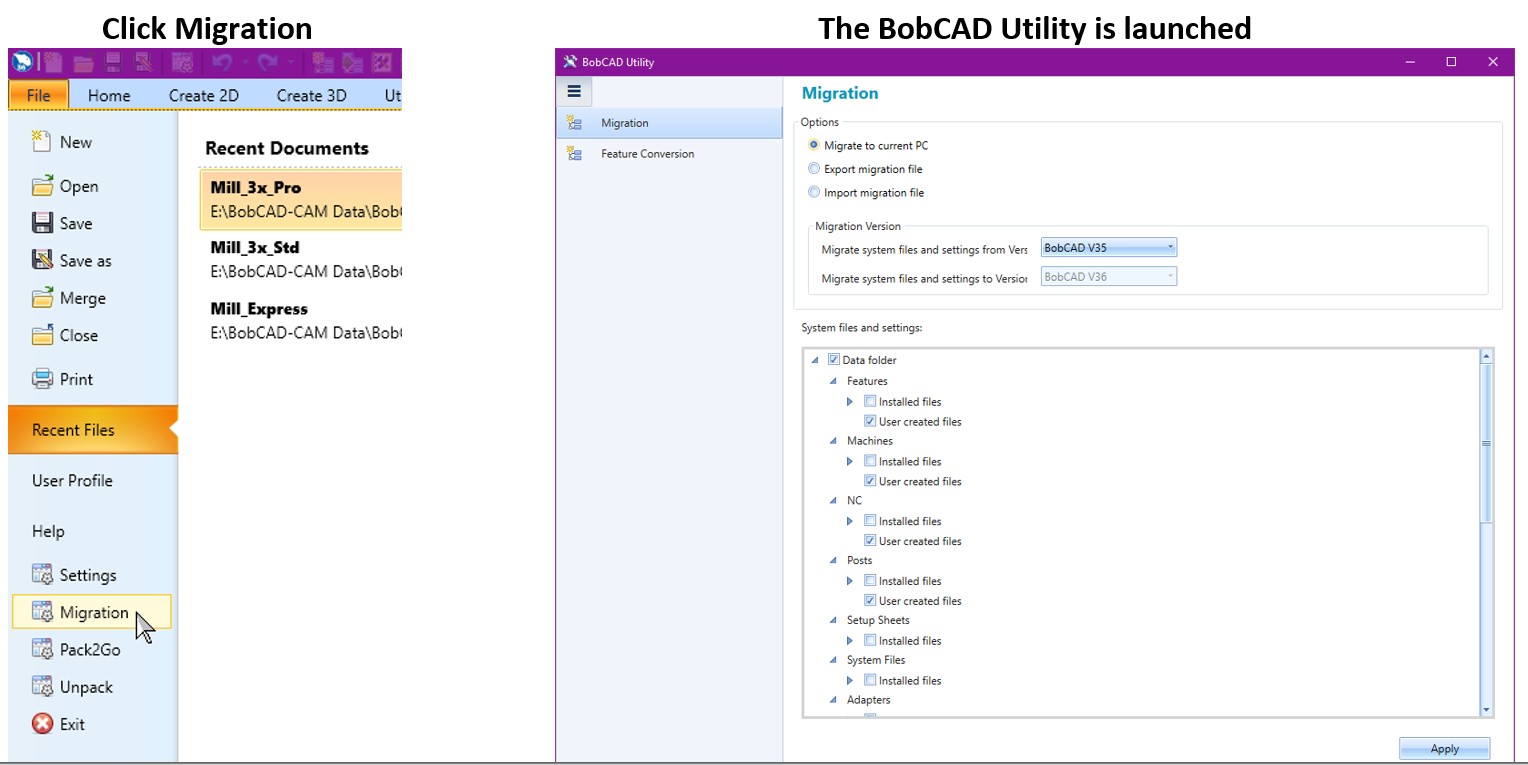

Migration

By popular demand, we now offer a simple migration tool to help you update into the latest and greatest BobCAD version without needing to manually copy individual items. With the new BobCAD Utility, simply select whether you are updating your version on the current computer, or exporting to a new PC. You can then select the version you’re migrating from, and to, and even update saved features to templates!

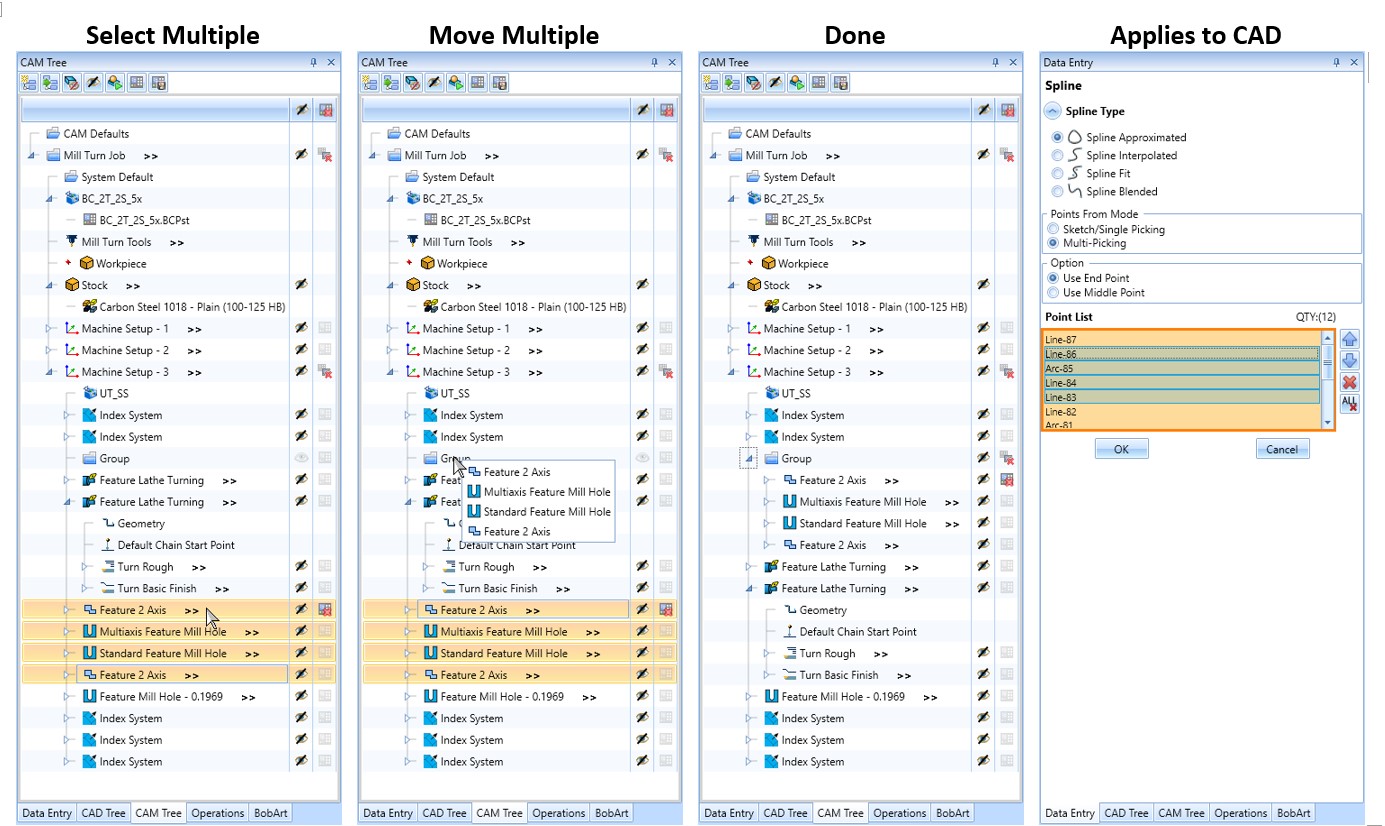

Multiple selection in picking boxes

Multiple selection now works for items in the CAM Tree, Geometry Picking Dialogs, and picking boxes in CAD features! Easily select multiple items to interact with for the first time ever!

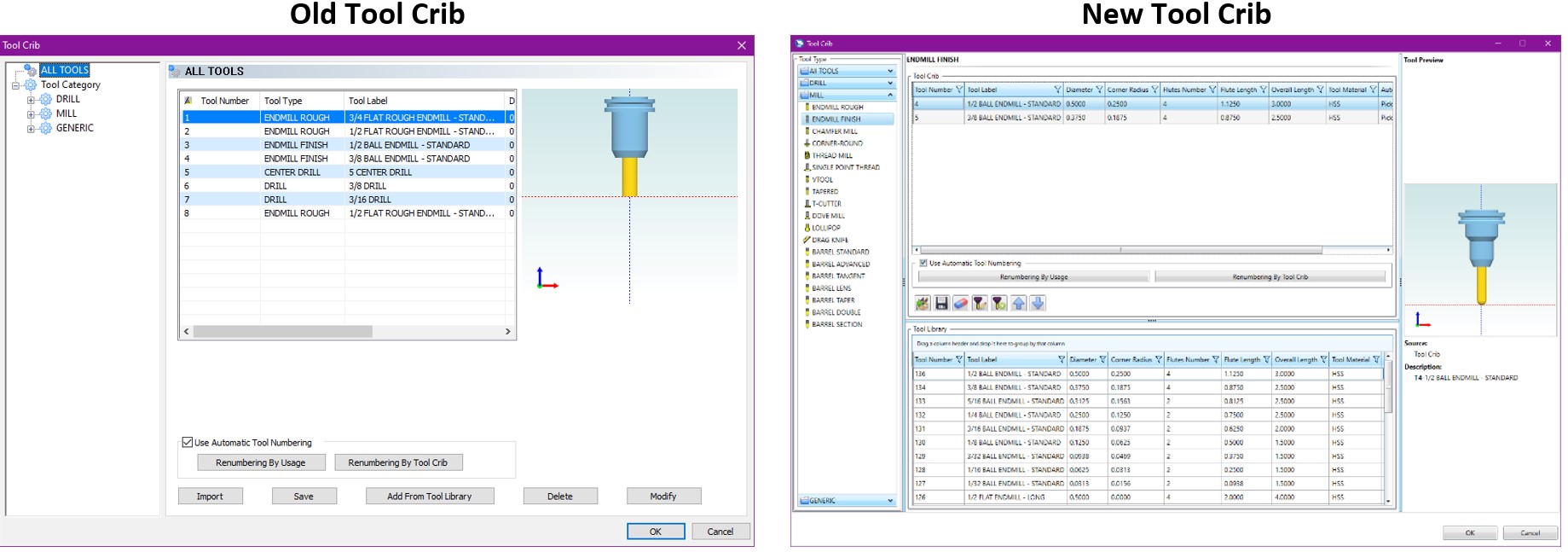

Redesigned Tool Crib

With our redesigned Tool Crib, you no longer need to open the Tool Library as a separate window and add your tools one at a time! The Tool Library is visible in the same window, you can select multiple tools to drag into the crib at the same time, and even save tools from the Tool Crib to your Tool Library for the first time!

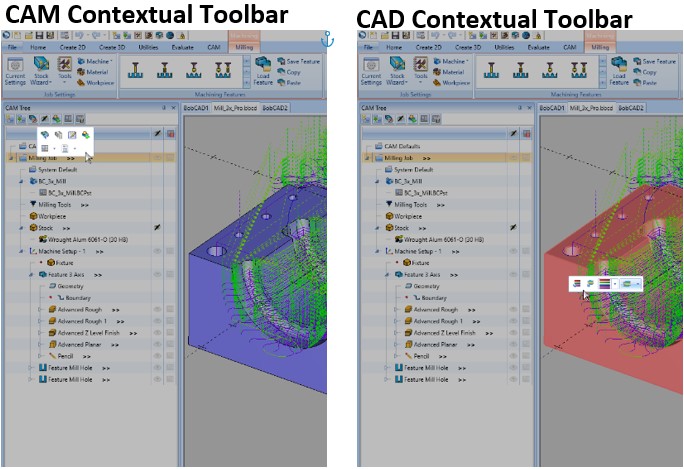

Contextual Toolbar

The new contextual toolbars give you easy access to the most frequently used commands! In this version, there’s really no need to right-click items to then search through the context menu to find the desired command. Simply left-click the item once and the Contextual Toolbar appears, allowing access to the commands you use time and time again!

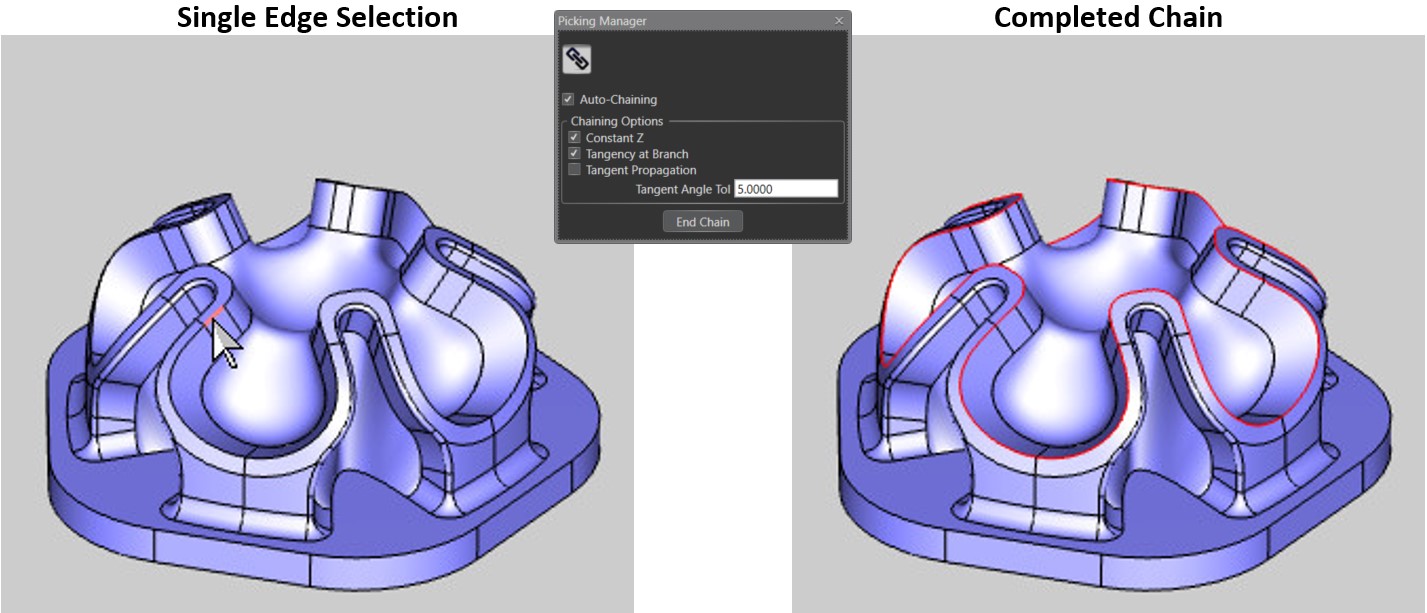

Picking Manager

The new chain selection options give you an enormous amount of power to select entire chains, from wireframe and solids alike, with speed and ease! Whether you’re selecting geometry for CAD features or assigning geometry to CAM features, these new options have you covered!

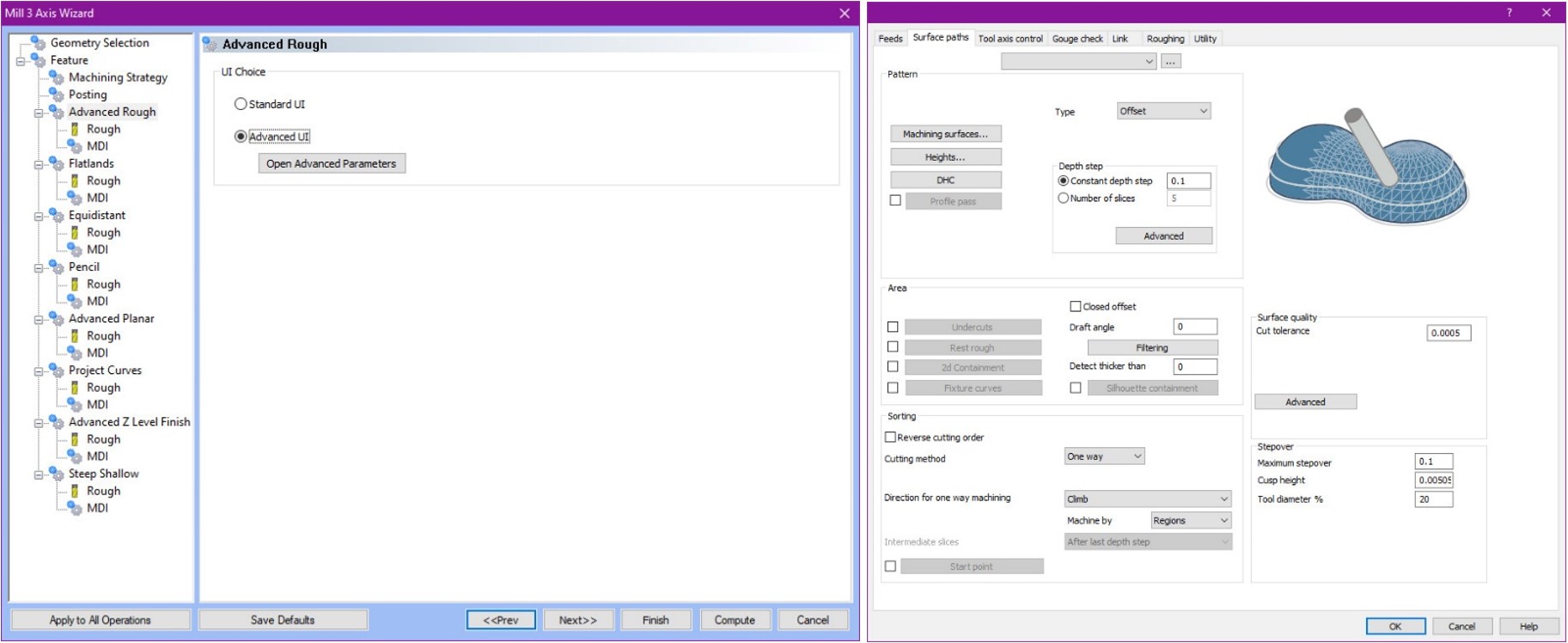

Advanced UI

When programming, controlling the toolpath can represent minutes or hours in cutting times. For this reason, we have developed the Advanced Interface of BobCAD CAM V36 Mill Pro, where our users will have unprecedented control over every detail of their programming process.

- Unlock the potential of six specialized link types, tailored to specific machining areas.

- Choose from a diverse selection of 15 lead-ins and lead-outs, ensuring precision in toolpath entry and exit.

- Harness the capability to create intricate patterns, execute precise rotations, and employ toolpath mirroring for unparalleled control.

- Execute undercuts seamlessly across all Pro strategies, expanding your machining capabilities.

- Streamline your setup process with the new stock definition dialog, allowing you to define boundaries effortlessly using your stock material.

This is the ultimate powerhouse for achieving precision, control, and efficiency in your machining operations

Get the premium control at the pro level.

Accelerate Model to Production At Lower Costs

V36 was updated to make physical production of CAD designs faster. BobCAD-CAM is focused on design to machine compatibility, allowing for fewer errors in data translation than any other solution in the marketplace. With compatibility for over 100+ machines, BobCAD-CAM V36 is the ultimate CNC solution.

Available Languages

The BobCAD-CAM V36 release is available in the following languages: English, Spanish, Turkish, German, Japanese and Korean.

WireEDM Module for V36

2 Axis, 2 Axis with Taper, Land and Taper and 4 Axis Machining

With the new operation Tree, programming and managing Wire EDM operations is more efficient and faster. The Wire EDM module supports 2 Axis, 2 Axis with Taper, Land and Taper, and 4 Axis machining to handle all your wirepath creation needs.

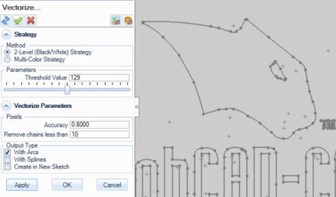

BobART Improvements

BobART has received a workflow overhaul to help you get the results you’re looking for quickly. We have improved the Raster to Vector dialogue by having it open directly in the Data Entry Manager. This allows you to view the image in the graphics area as you normally would. Zoom in, Pan, and even Rotate to put as much focus on the area whichever areas interest you the most!

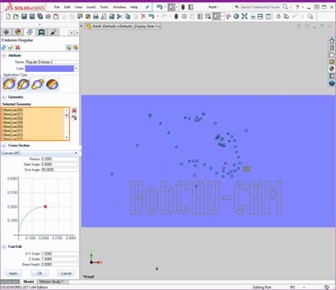

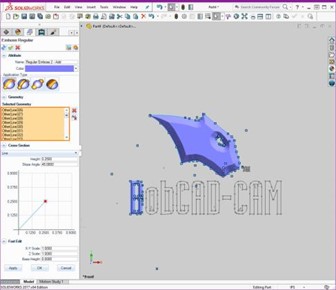

Oh, and did we mention we now have a “Make as Solid” option? In the past, while you could do things to give a height to your model, extended walls were really the only thing added. You were still left with what was essentially a mesh surface draped down to the floor. Looking behind the model, as seen in the first image, it was apparent the mesh was not closed. With this new option, as you can see in the following image, the mesh is closed creating a water-tight mesh. This expands the possibilities of what can be done with your final model, and we’ve even added unit options allowing you to specify the units to use when exporting STL Components!

Reduce Errors With Full Integration

Faster more accurate adjustments to toolpaths for quicker turnaround from design to engineering to manufacture. Less errors save time and materials.

Real People, Real Results

“I’m impressed with the new deburring toolpath, how it breaks all my part edges with a single machining feature.”

–Advantage Plan Member Since 2017, Lars Mommer | R&D Machining

BobCAD-CAM V36 Now Available!

Schedule a demo by calling 877-262-2231